Analysis of environmental challenges and sealing solutions faced by outdoor electrical equipment

Date:Sep 13, 2025

Introduction: With the widespread deployment of industrial automation equipment and infrastructure, the reliability of electrical components such as switches and indicator lights in complex environments has become a focus of industry attention. This is particularly true in outdoor environments, where humidity, dust, or chemical corrosion are present, putting component performance and lifespan under severe test. This article will explore the main failure mechanisms of electrical components in these environments and effective sealing design strategies.

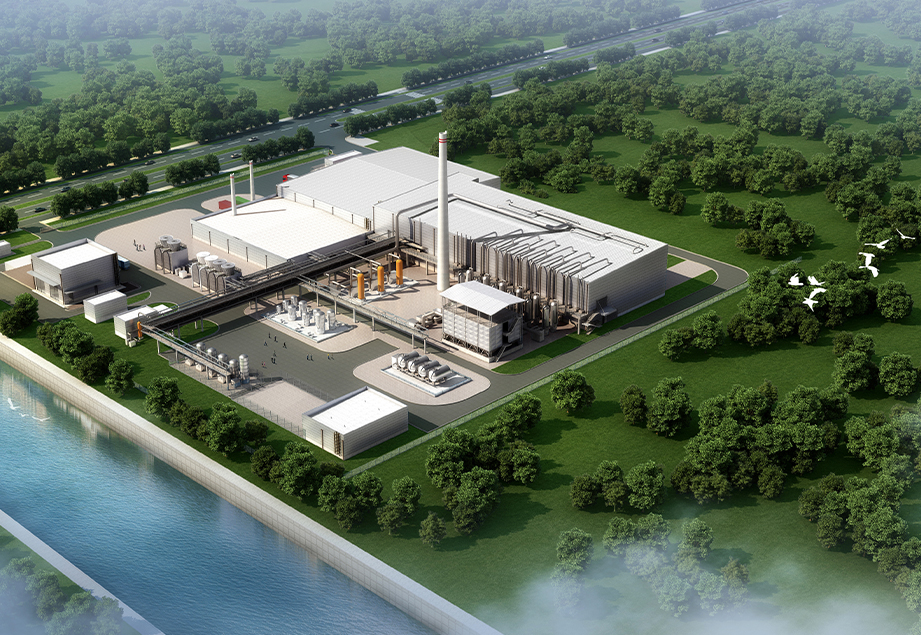

Electrical control components are increasingly used in outdoor or harsh industrial environments, such as new energy charging stations, port machinery, medical disinfection equipment, and food processing lines. These environments are prone to challenges such as moisture, dust, salt spray, oil, chemical corrosion, and extreme temperature fluctuations, which can easily lead to premature component failure.

Common failure modes include:

Media intrusion: Moisture and dust penetrate the component interior, causing circuit shorts, contact oxidation, or rust.

Seal aging: Ordinary rubber or plastic seals are susceptible to hardening, embrittlement, or swelling under the influence of ultraviolet light, high and low temperature cycles, or chemicals, losing their elasticity and causing seal failure.

Mechanical stress: Internal and external pressure differences caused by temperature fluctuations, or structural stress during installation, can compromise the integrity of the sealing interface.

Core technologies for improving environmental resistance include:

Material innovation: Using highly weather-resistant metal housings (such as stainless steel and zinc alloy) and specialized silicone rubber sealing materials to resist corrosion, aging, and wear.

Structural Design: A multi-stage sealing strategy (such as a combination of axial and radial seals), an integrated metal housing, and precision-machined mating interfaces fundamentally block intrusion paths.

Standard Certification: Rigorous verification according to the International Protection Classification (IP Code), UL, and industry standards (such as IEC 60529) provides an objective measure of product sealing performance.

Conclusion:

The lifecycle reliability of a component can no longer be determined solely by a single parameter; instead, it requires systematic design and verification encompassing multiple dimensions, including materials science, structural mechanics, and surface treatment. Selecting suppliers with relevant technical expertise and testing capabilities has become crucial for equipment manufacturers to enhance their overall product competitiveness and mitigate after-sales risks.

About Wandu Electric:

Zhejiang Wandu Electric Co., Ltd. is a professional manufacturer of industrial control components, including metal pushbutton switches, indicator lights, and emergency stop switches. The company specializes in the research and application of sealing technologies. Its professionally tested, airtight metal switch products provide reliable control interface solutions for equipment in outdoor and harsh industrial environments.

русский

русский Español

Español