How Do Economical Metal Pushbutton Switches Control Costs?

Economical Metal Pushbutton Switches are designed to provide the mechanical strength of metal housings while keeping overall system costs under control. They are commonly used in applications where basic switching functions are required but large production volumes or tight budgets limit component spending.

Cost control does not simply mean using thinner materials. Instead, it often involves streamlined internal structures, simplified contact configurations, and standardized dimensions that reduce manufacturing complexity. These switches typically support common voltage and current ranges used in control circuits rather than high-load power switching.

For users, the practical consideration lies in matching expectations with specifications. Economical models are well suited for low-frequency operation, non-critical signaling, and environments with moderate exposure to dust or vibration. They may not include advanced sealing or specialized coatings, so understanding the installation environment helps prevent premature wear. When applied appropriately, they offer a functional balance between metal durability and controlled cost.

Why Is an Industrial Push Button Switch Built Differently?

An Industrial Push Button Switch focuses on consistent performance in demanding operating conditions. These switches are commonly found in manufacturing lines, material handling systems, and control panels exposed to vibration, frequent use, or environmental stress.

The difference is evident in both mechanical and electrical design. Industrial versions often feature reinforced actuators, higher mechanical life ratings, and contact systems intended for repeated operation. Housing materials and sealing structures are selected to address dust ingress, moisture, and temperature variation commonly encountered in industrial settings.

Another practical aspect is standardization. Industrial push buttons often follow widely recognized mounting sizes and labeling conventions, which simplifies panel design and replacement. This consistency reduces downtime during maintenance, as technicians can identify and replace components without extensive modification. While these switches may carry a higher unit cost than economical options, their suitability for continuous operation often aligns better with industrial workflows.

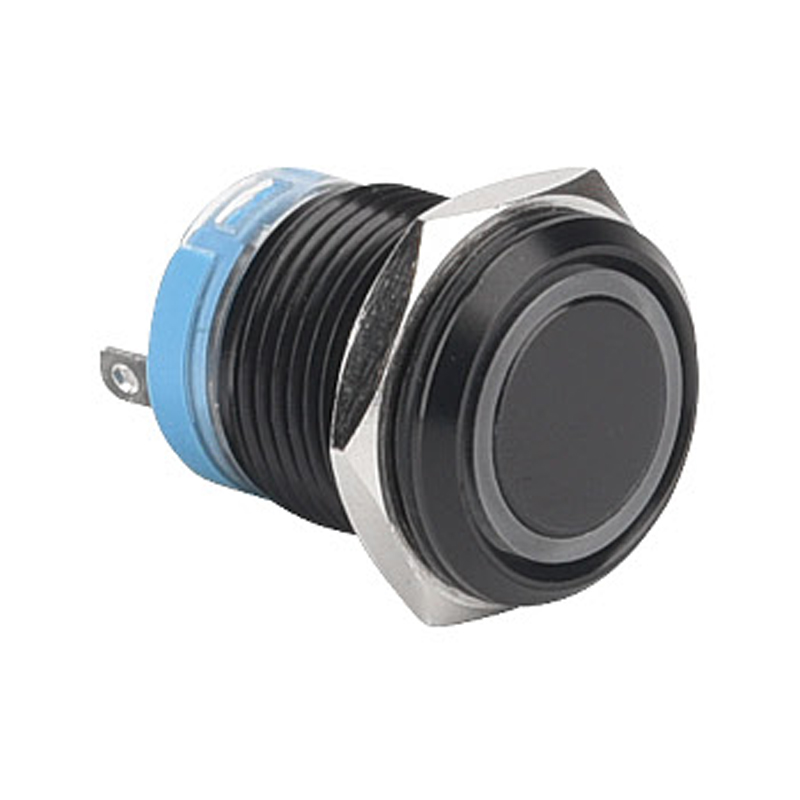

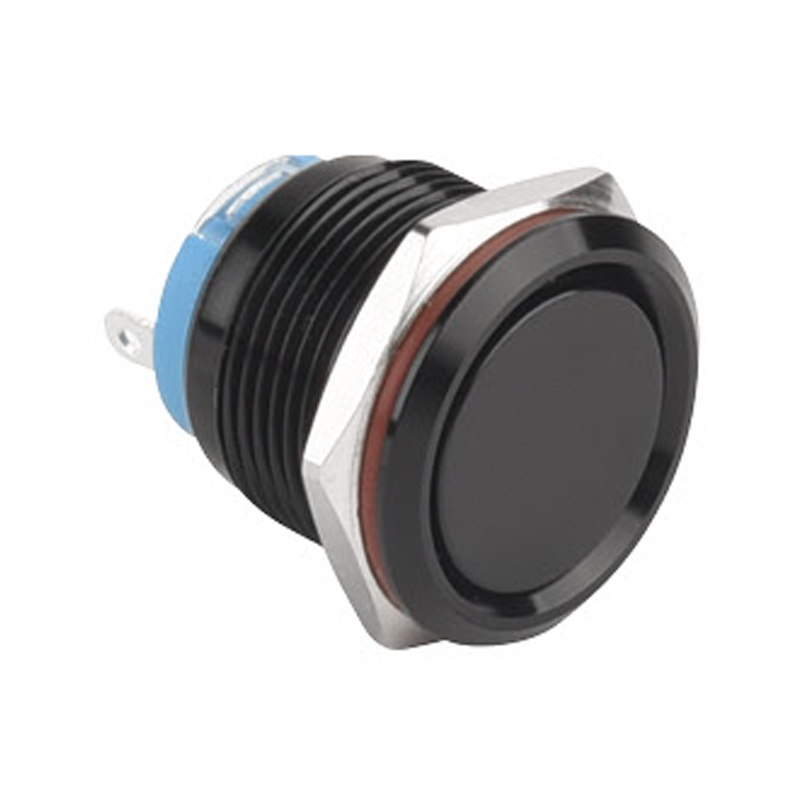

What Is the Purpose of a Ring-Shaped Metal Switch?

A Ring-Shaped Metal Switch is distinguished by its illuminated ring surrounding the actuator. The ring serves as a visual indicator rather than a structural feature, helping users quickly identify switch status or location.

In practical use, the illuminated ring can indicate power availability, active selection, or standby status, depending on how it is wired. This is particularly useful in low-light environments or on densely populated control panels where multiple switches are installed close together. The visual cue reduces hesitation and helps operators confirm actions without relying solely on labels.

Metal construction adds another layer of functionality by providing resistance to mechanical impact and surface wear. However, users should pay attention to illumination voltage, wiring separation between the indicator and contact circuits, and heat dissipation in continuous-on scenarios. When these factors are considered during design, ring-shaped switches contribute to clearer human-machine interaction rather than decorative complexity.

How Should Users Decide Between These Switch Types?

The choice often depends on operational priorities rather than appearance. Cost-sensitive projects benefit from economical metal switches when usage conditions are predictable. Industrial environments with high interaction rates and environmental exposure call for purpose-built industrial push buttons. When user feedback and visibility are critical, ring-shaped designs help communicate system status more intuitively.

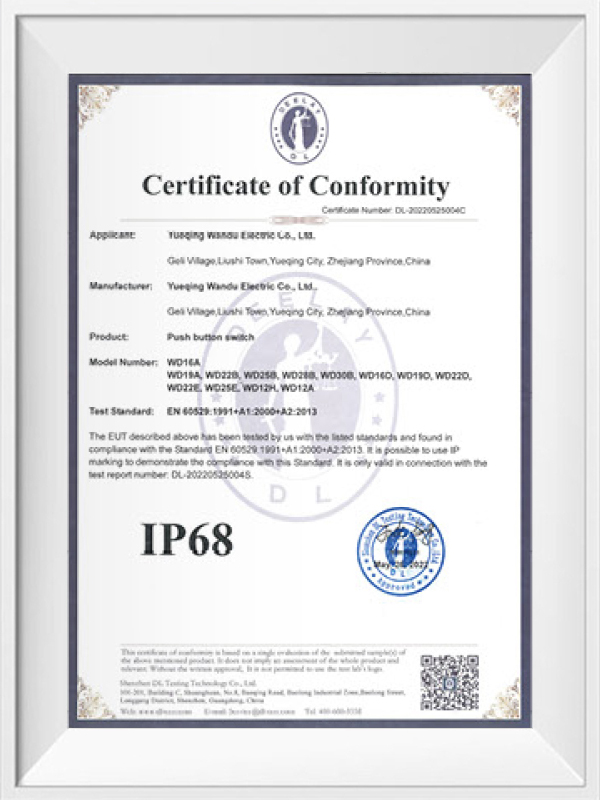

It is also common for these characteristics to overlap. Some industrial switches include ring illumination, while certain economical models may still meet light industrial needs. Reviewing specifications such as mechanical life, ingress protection, and electrical ratings provides more clarity than relying on category names alone.

Practical Perspective for Long-Term Panel Design

Switch types illustrate how control components adapt to different constraints. Economical Metal Pushbutton Switches emphasize cost awareness, Industrial Push Button Switch designs address durability and consistency, and Ring-Shaped Metal Switch options focus on visual communication. A thoughtful combination of these elements helps create panels that are understandable, maintainable, and suited to real operating conditions. Over time, this alignment between design intent and application reduces user error and supports smoother equipment operation without unnecessary complexity.

русский

русский Español

Español