How Do High Current Emergency Stop Switches Handle Load?

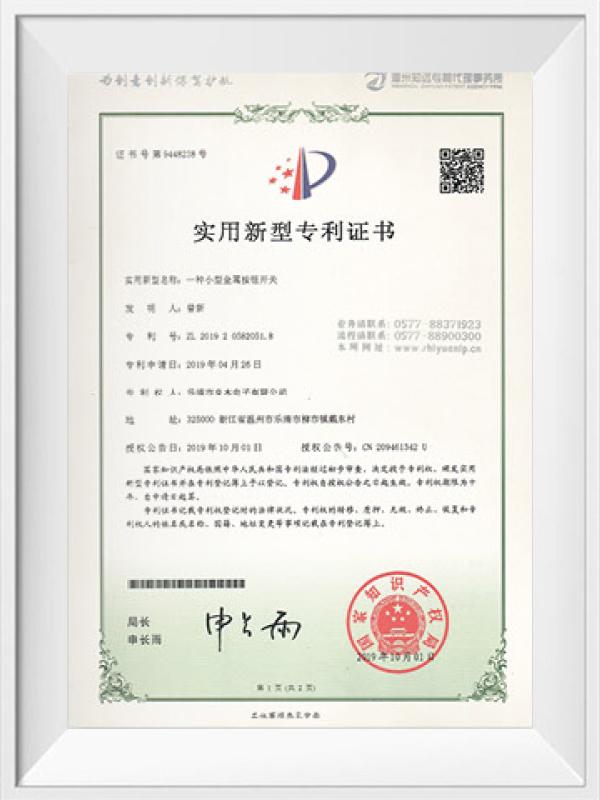

High Current Emergency Stop Switches are specifically designed to interrupt circuits carrying significant electrical current. Unlike standard emergency stops intended for signal-level circuits, these switches can directly disconnect motor power, heaters, or other high-load devices without relying on auxiliary relays.

From a design perspective, high current switches use robust contacts and thick conductive paths to manage arcing and heat buildup during disconnection. Materials like silver alloys or plated copper are commonly employed to maintain consistent contact performance over repeated cycles.

Practical considerations for users include evaluating the voltage and current rating against the connected equipment. Oversizing the switch for the expected load ensures both safety and durability, while undersizing may cause premature contact wear or welding. Integration with existing control architecture must also account for switching speed and potential transient effects to prevent electrical damage or nuisance tripping.

Why Use Push Pull Emergency Stop Switches in Panels?

Push Pull Emergency Stop Switches provide a tactile latching mechanism where the operator pushes the button to activate the stop and pulls it to reset. This design ensures that the emergency condition is maintained until a conscious reset occurs, reducing the risk of accidental restarts.

The push-pull operation is particularly effective in high-stress or high-traffic environments. The large actuator surface allows operators to engage the switch quickly, even with gloves or in low-visibility conditions. This type of switch is often mounted on control panels or machinery consoles where a clear, unambiguous stop command is required.

Users should also consider the ergonomics and spacing of these switches. Placement should allow immediate access without obstruction, while ensuring that the pull-to-reset action does not interfere with nearby controls. Combining proper positioning with push-pull functionality helps maintain both safety and operational clarity.

What Benefits Does an Emergency Stop Button With Enclosure Offer?

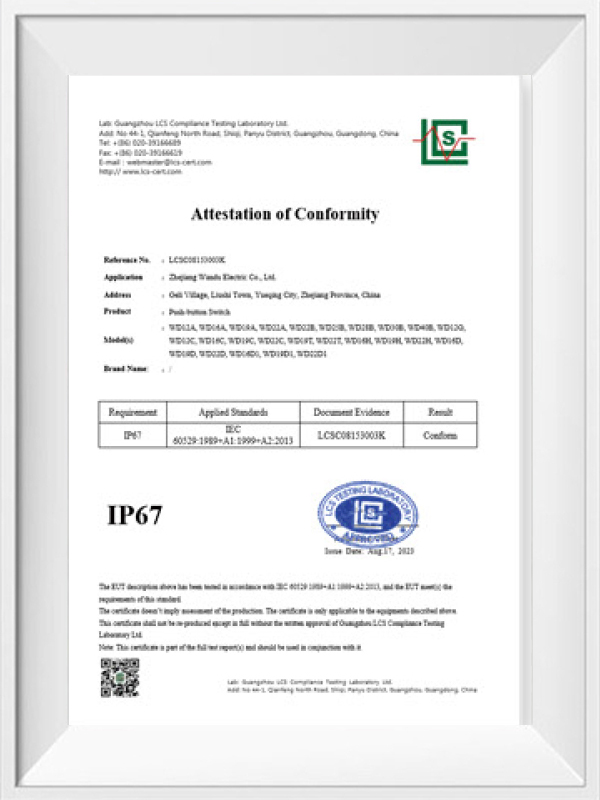

An Emergency Stop Button With Enclosure integrates the stop actuator within a protective housing. This enclosure shields the switch from environmental hazards such as dust, water, or impact, extending service life and maintaining functionality in challenging conditions.

Enclosures can range from simple IP-rated boxes to robust industrial housings with transparent covers and locking mechanisms. This design prevents accidental activation from unintended contact, while maintaining visibility and access for operators. Some enclosures also allow for auxiliary devices, like indicator lights, to be integrated, providing immediate visual feedback on system status.

For practical deployment, users should review the IP rating and material of the enclosure to ensure it matches operational conditions. Consideration should also be given to mounting method, cable entry points, and ease of maintenance. An appropriately enclosed emergency stop switch improves both durability and reliability of the safety system.

How Should These Emergency Stop Devices Be Applied Together?

While each type of emergency stop switch serves a unique purpose, they often work together in complex control environments. High Current Emergency Stop Switches address heavy electrical loads, Push Pull Emergency Stop Switches focus on deliberate operator action, and Emergency Stop Button With Enclosure protects against environmental and accidental interference.

Choosing the right combination involves assessing the electrical requirements, operator accessibility, and environmental conditions. Proper integration ensures that emergency stop functions remain responsive and predictable, reducing risks during critical situations.

русский

русский Español

Español