How Does a High-Current Button Handle Electrical Load?

A High-Current Button is intended to switch circuits that carry significantly higher current than standard control signals. These buttons are commonly used in power distribution equipment, motor control panels, battery systems, and industrial machinery where currents can reach tens of amperes or more.

The key technical difference lies in the internal contact design. High-current buttons use thicker contact materials, optimized contact geometry, and stronger spring mechanisms to reduce contact resistance and manage heat generation during operation. This is important because excessive resistance at the contact point can cause localized heating, which may shorten component life or affect system stability.

Another consideration is switching frequency. High-current buttons are often used for infrequent but decisive actions, such as energizing a circuit or disconnecting a load. If frequent switching is required, users should carefully review the electrical life rating under load conditions rather than relying on mechanical life alone. Proper matching of voltage and current ratings to real operating conditions is one of the practical steps to reduce unexpected failures.

Why Is a Test Button Switch Used for System Verification?

A Test Button Switch serves a diagnostic role rather than a primary control function. It allows operators or maintenance personnel to simulate a specific condition without altering the normal operation of the system. This is especially useful in safety circuits, alarm systems, and monitoring devices.

For example, a test button may be wired to check whether an indicator lamp, buzzer, relay, or protective circuit responds as expected. By pressing the test button, users can confirm that the downstream components are functioning without waiting for an actual fault or event to occur. This reduces uncertainty during inspections and supports preventive maintenance routines.

From a design standpoint, test buttons are typically momentary and clearly labeled to avoid confusion with operational controls. The wiring logic is equally important: the test circuit should not bypass essential protections or create unsafe states. Engineers often design test functions so they temporarily introduce a known signal rather than forcing a full operational change. This approach balances verification needs with system safety.

What Makes High Current Metal Pushbutton Switches Different?

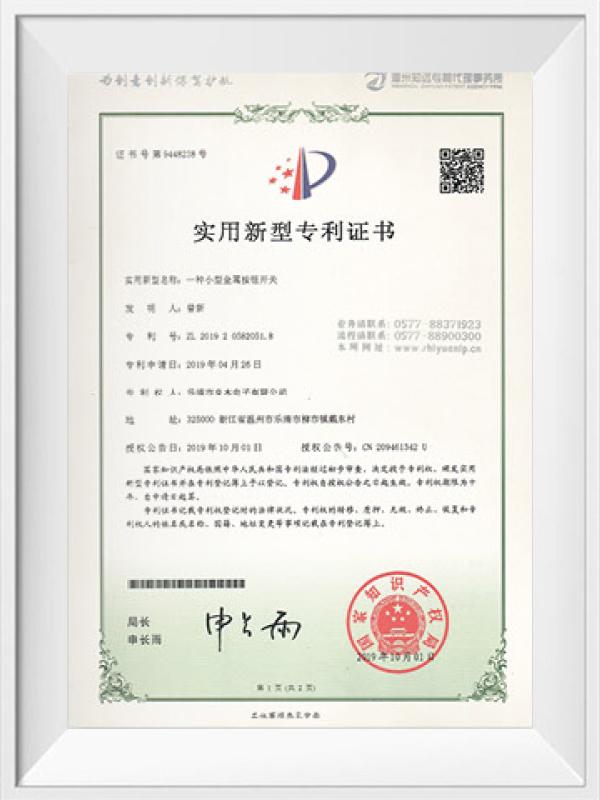

High Current Metal Pushbutton Switches combine two performance requirements: the ability to handle elevated current and the mechanical strength of a metal housing. The metal body is not merely cosmetic; it provides resistance to impact, vibration, and environmental exposure that can affect long-term operation.

In industrial or outdoor environments, metal housings help protect internal components from deformation and provide better resistance to dust, moisture, and temperature variation. Depending on the application, materials such as stainless steel or aluminum alloy may be selected to address corrosion concerns.

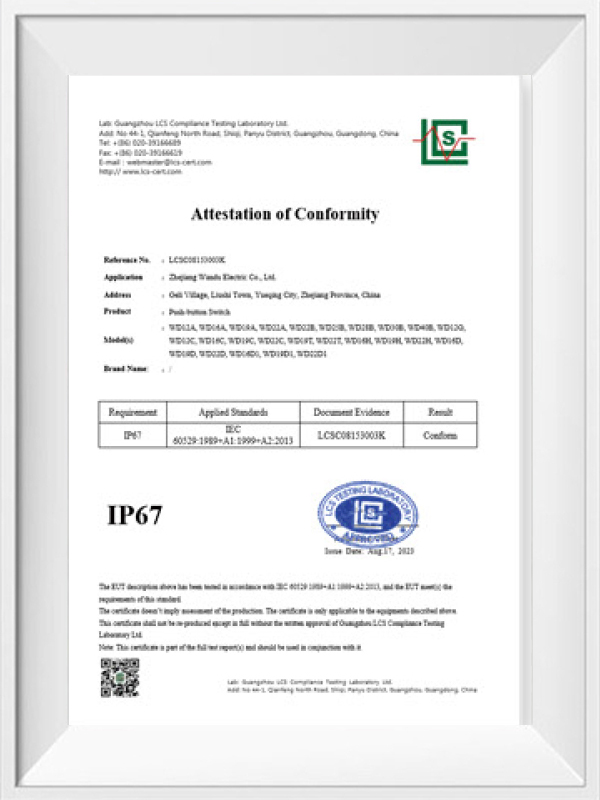

However, metal construction also introduces design considerations. Proper insulation between live parts and the housing is critical, as is grounding where required. Many high current metal pushbuttons are designed with reinforced insulation and sealing structures to meet relevant safety standards. Users should also pay attention to mounting torque and panel thickness, as metal-bodied switches often have tighter mechanical tolerances than plastic alternatives.

How Should Users Select the Right Button Type?

Choosing between these button types starts with understanding the function rather than focusing on appearance. If the circuit carries substantial current, the electrical rating and contact design take priority. When regular system checks are needed, a dedicated test button prevents misuse of operational controls. In physically demanding environments, metal housings support structural stability and consistent actuation.

It is also common to see overlap. A test button may still need to handle moderate current, or a high-current button may be built into a metal enclosure. Reviewing datasheets for current rating under specific voltage levels, duty cycles, and environmental conditions provides clearer guidance than relying on nominal ratings alone.

русский

русский Español

Español