What Defines a Standard Metal Buzzer in Practice?

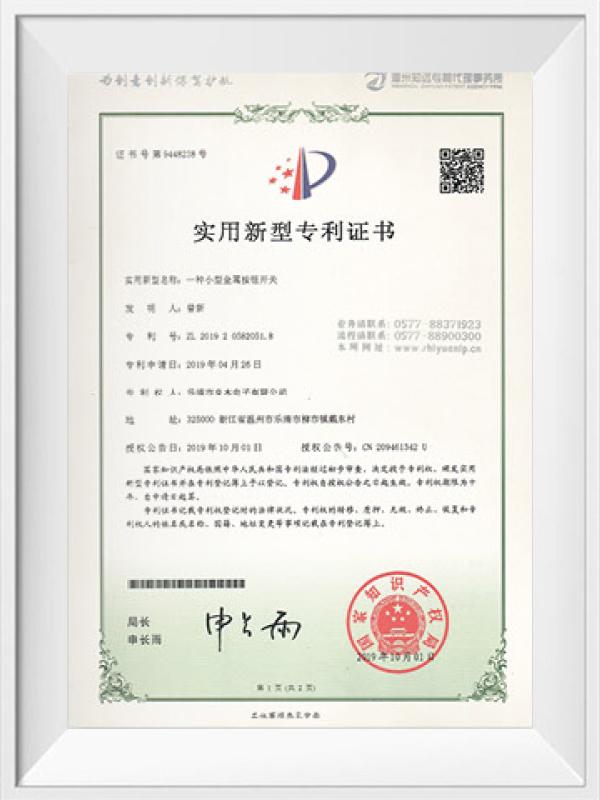

A Metal Buzzer is primarily characterized by its metal housing, which provides structural stability compared with plastic alternatives. The metal shell helps protect internal components from minor impacts, vibration, and surface wear, making it suitable for general-purpose control panels and equipment interfaces.

From an electrical perspective, metal buzzers are used to convert electrical signals into audible alerts for status indication, warnings, or user feedback. Typical applications include fault notifications, operation confirmation, or timing alerts. Their sound pressure level is generally moderate, intended to be clearly audible within a localized area rather than across large spaces.

When selecting a metal buzzer, users should consider operating voltage, current consumption, and sound pattern. Continuous tone and intermittent tone options serve different communication purposes. Additionally, mounting method and panel thickness matter, as metal housings often require secure fastening to avoid resonance or unwanted vibration noise during operation.

Why Are Industrial Metal Buzzers Built for Tough Conditions?

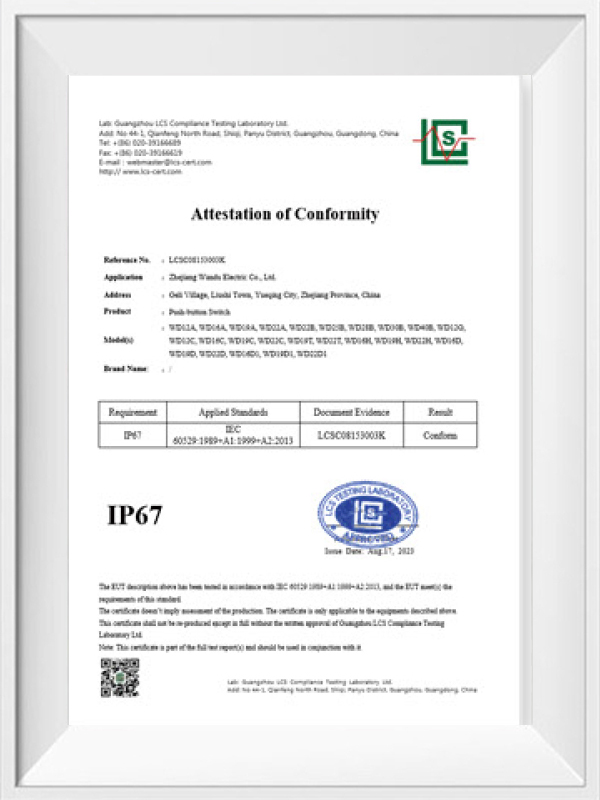

An Industrial Metal Buzzer is designed with long-term operation and environmental resistance in mind. These devices are commonly installed in factories, processing plants, and outdoor equipment where dust, moisture, and temperature variation are part of daily operation.

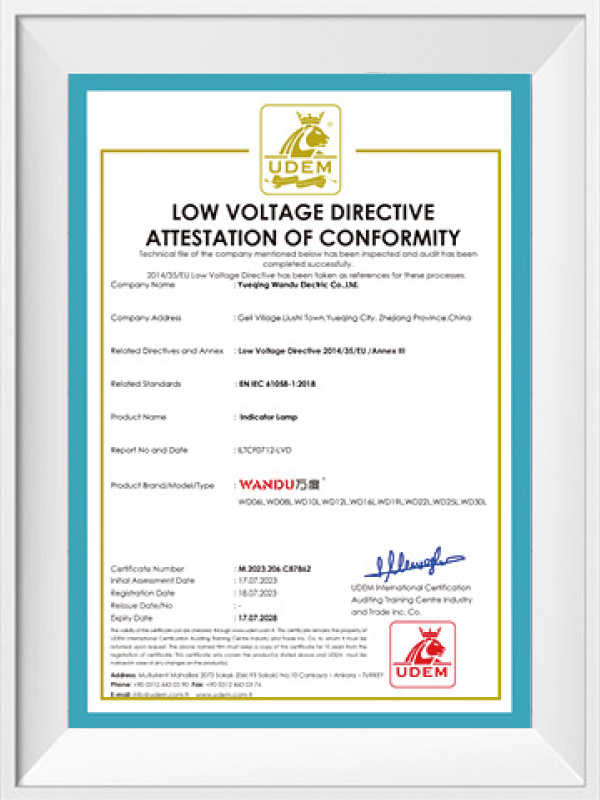

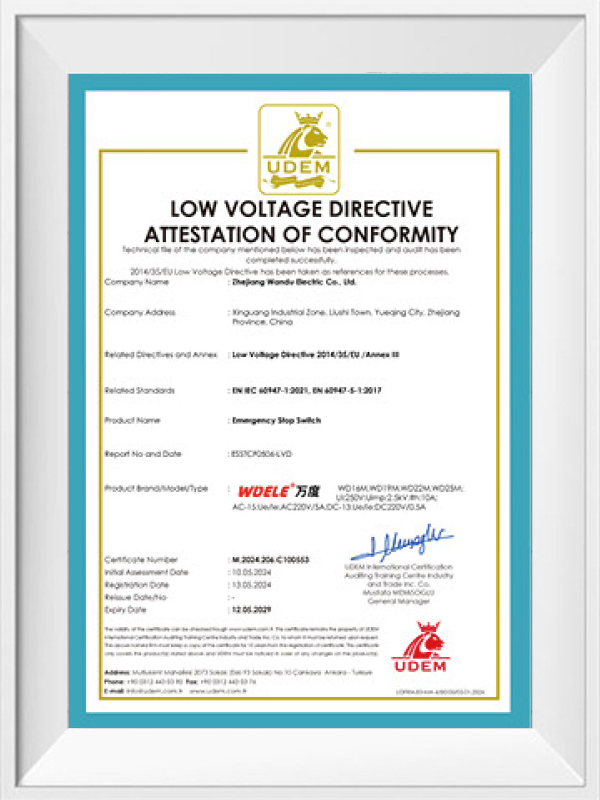

The difference lies in construction details rather than basic function. Industrial designs often feature improved sealing, reinforced internal structures, and materials chosen for corrosion resistance. This allows the buzzer to maintain consistent sound output even after prolonged exposure to challenging conditions.

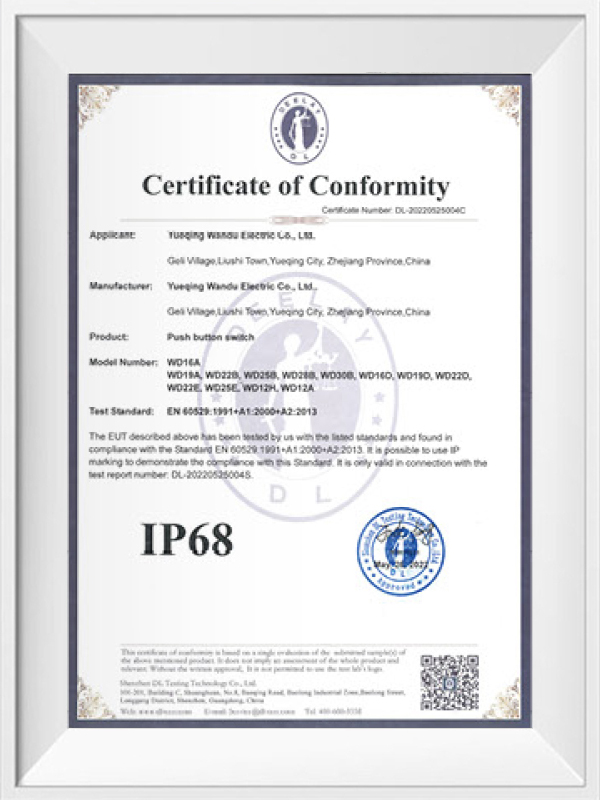

Another key consideration is duty cycle. In industrial settings, buzzers may activate frequently or remain active for extended periods during alarms or process alerts. Industrial metal buzzers are typically specified with higher endurance for such use, reducing the risk of coil fatigue or sound degradation. For users, checking ingress protection ratings and allowable operating temperature ranges is more meaningful than focusing solely on sound level.

When Is a High-Decibel Metal Buzzer Necessary?

A High-Decibel Metal Buzzer is selected when sound must travel farther or compete with significant background noise. These devices are used in environments such as large workshops, loading areas, or machinery zones where ambient noise can mask standard alerts.

The higher sound pressure level is achieved through optimized internal acoustics, stronger drive mechanisms, or resonant housing design. However, higher output also introduces practical considerations. Prolonged exposure to loud sound can affect personnel comfort and compliance with workplace noise regulations. For this reason, high-decibel buzzers are often activated only during critical warnings or emergency conditions rather than routine notifications.

Proper placement is equally important. Mounting height, direction of sound emission, and enclosure design all influence how effectively the alert reaches its intended audience. Users should also verify voltage stability, as fluctuations can affect both sound level and tone consistency in high-output devices.

How Should Users Match Buzzers to Real Applications?

Choosing among these buzzer types starts with understanding the environment and purpose of the alert. A standard metal buzzer suits controlled indoor spaces with clear lines of communication. Industrial metal versions address durability and endurance in harsher conditions. High-decibel models focus on audibility across distance and noise.

It is also possible to combine features. Some industrial buzzers are designed to deliver higher sound output while maintaining sealed metal housings. Rather than relying on category labels alone, users benefit from reviewing technical parameters such as sound pressure level at specified distance, continuous operation limits, and environmental ratings.

Practical Perspective on Audible Signaling Design

Seen as part of a larger system, buzzers are not just sound sources but communication tools. Metal Buzzer designs emphasize structural stability, Industrial Metal Buzzer options focus on environmental resilience, and High-Decibel Metal Buzzer models address audibility challenges. A thoughtful selection process aligns sound output with context, ensuring alerts are heard when needed without becoming a source of confusion or fatigue. Over time, this balance supports clearer interaction between people and machines, reinforcing safety and operational awareness through sound rather than complexity.

русский

русский Español

Español