How Does an Indicator Light Communicate System Status?

An Indicator Light is the basic visual signaling device used in electrical and electronic systems. Its primary function is to provide a simple on/off visual cue linked to a specific condition, such as power presence, process activation, or fault detection.

In practice, indicator lights are connected directly to control circuits, relays, or controllers so that their state reflects real system behavior. Color selection plays an important role in clarity. Although conventions vary, green often represents normal operation, amber signals caution or standby, and red is associated with abnormal conditions. Consistent color usage across a panel helps operators interpret information quickly.

From a design standpoint, brightness, viewing angle, and mounting position influence effectiveness. An indicator light that is too dim may be overlooked, while excessive brightness can cause glare in enclosed spaces. Users should also consider voltage compatibility and current consumption, especially when retrofitting older panels with modern light sources.

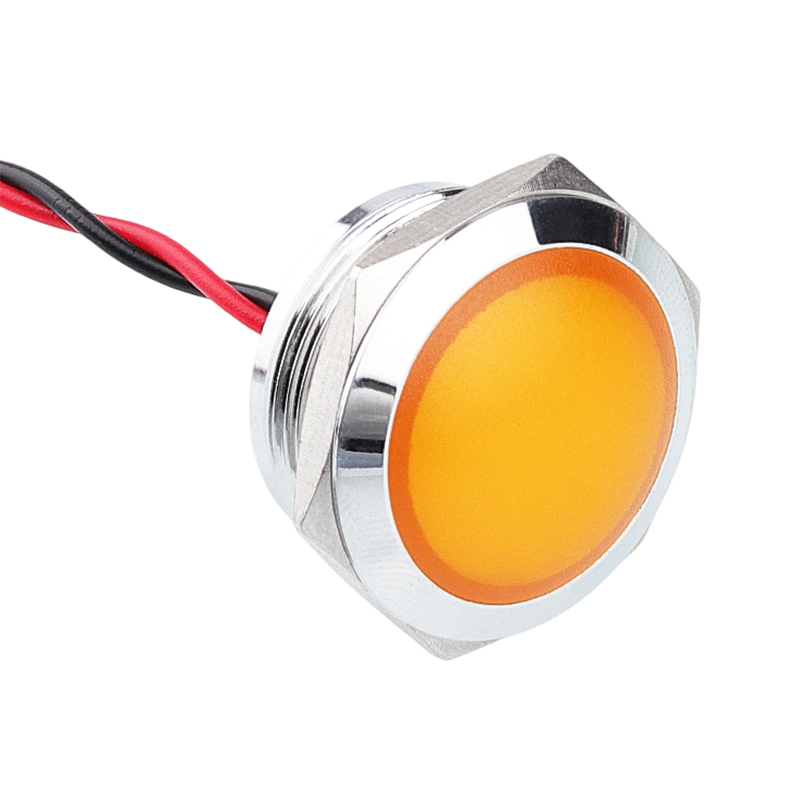

Why Use a Multi-Color LED Indicator?

A Multi-Color LED Indicator expands the information capacity of a single indicator by using different colors to represent multiple states. This is typically achieved through bi-color or tri-color LEDs that change color based on wiring configuration or control signals.

The main advantage is space efficiency. Instead of installing several individual indicator lights, one multi-color unit can convey several conditions. For example, a machine may display green for running, blue for standby, and red for fault. This reduces panel complexity and simplifies labeling.

However, users should be mindful of clarity. If color changes are too subtle or poorly documented, operators may misinterpret signals. Clear legends or standardized color logic are essential. Additionally, control systems must be designed to avoid ambiguous states, such as two colors appearing simultaneously unless that condition is intentional and well understood.

Electrical design also matters. Multi-color LED indicators may require separate control lines or specific voltage arrangements for each color. Reviewing wiring diagrams and ensuring compatibility with control outputs helps avoid installation issues.

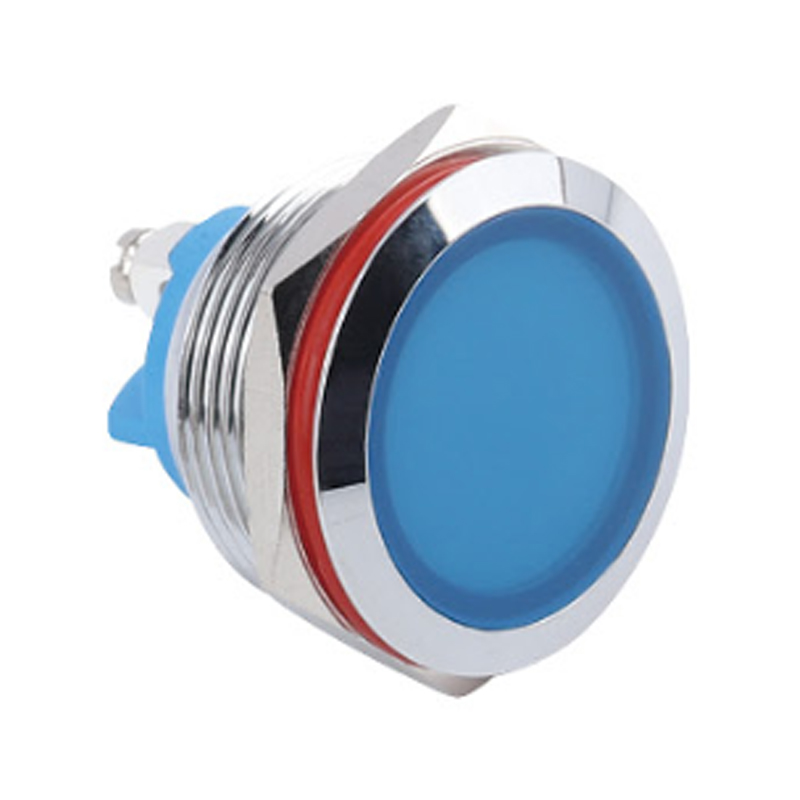

What Are the Advantages of Metal Indicator Lights?

Metal Indicator Lights are distinguished by their housing material rather than their light source. The metal body provides mechanical strength and environmental resistance, making these indicators suitable for industrial or outdoor applications.

Metal housings protect internal components from impact, vibration, and surface wear. They also perform better in environments exposed to oils, dust, or frequent cleaning. Depending on material selection, such as stainless steel or aluminum alloy, metal indicator lights can offer improved resistance to corrosion.

There are practical considerations as well. Metal housings require proper insulation and grounding to maintain electrical safety. Installation torque and panel thickness must be matched to the indicator design to ensure a secure fit without deforming the housing. When these factors are addressed, metal indicator lights support long-term use in demanding conditions.

How Should Users Choose Between These Options?

Selecting the right indicator solution begins with understanding how much information needs to be communicated and where the device will be installed. A basic indicator light suits simple, clearly defined signals. Multi-color LED indicators help condense information where panel space is limited. Metal indicator lights address durability and environmental exposure.

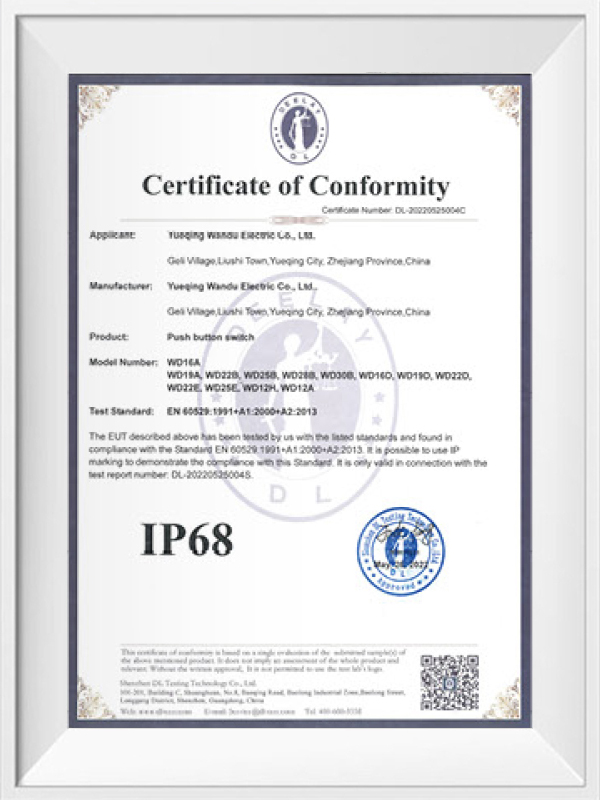

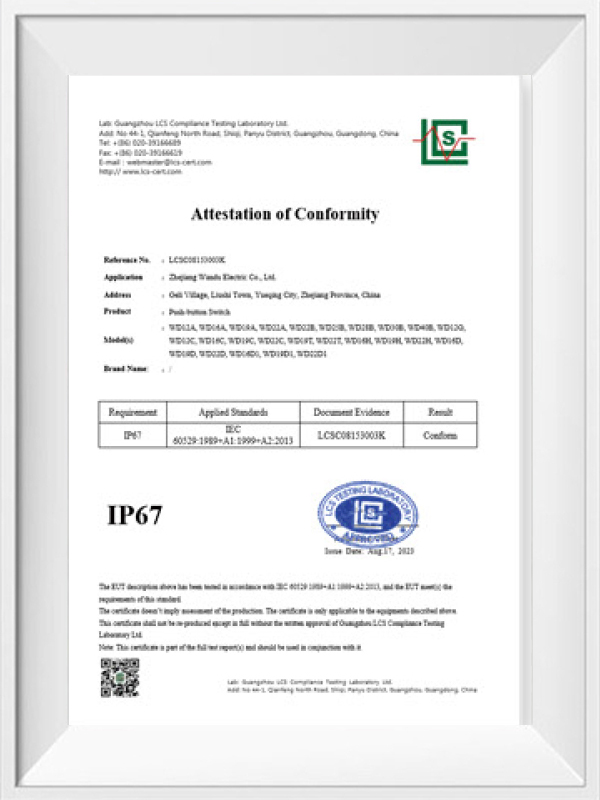

These features can also overlap. A multi-color LED indicator may be housed in a metal body, combining information density with mechanical strength. Rather than relying on product names alone, users benefit from reviewing specifications such as brightness level, ingress protection rating, operating voltage, and mounting requirements.

русский

русский Español

Español