How Does a Reset Button Switch Restore System Operation?

A Reset Button Switch is used after a fault or emergency stop has occurred. Its purpose is not to restart machinery directly, but to acknowledge that a stop condition has been addressed and allow the control system to return to a ready state.

In many safety circuits, pressing an emergency stop opens the control loop and brings motion or power to a halt. Once the issue has been identified and resolved, the reset button provides a deliberate human action that confirms it is safe to proceed. This separation between “reset” and “start” is intentional. It prevents machines from restarting immediately when an emergency stop is released.

From a wiring perspective, reset buttons are commonly momentary and connected to safety relays or controllers. They often require specific timing or conditions—such as all guards being closed—before the reset signal is accepted. For users, placement is important: reset buttons should be visible and accessible, but not positioned where they could be pressed unintentionally. This ensures the reset action remains a conscious decision rather than a habit.

Why Are Waterproof Emergency Stop Pushbuttons Necessary?

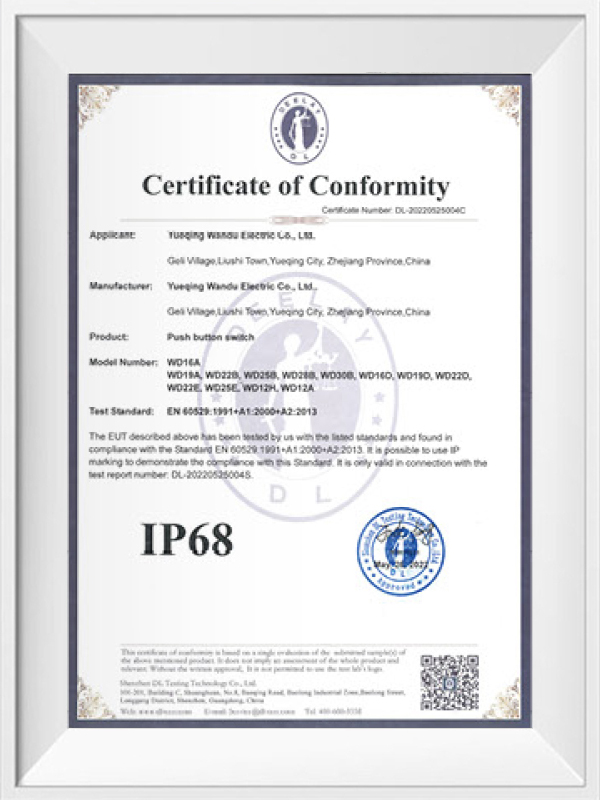

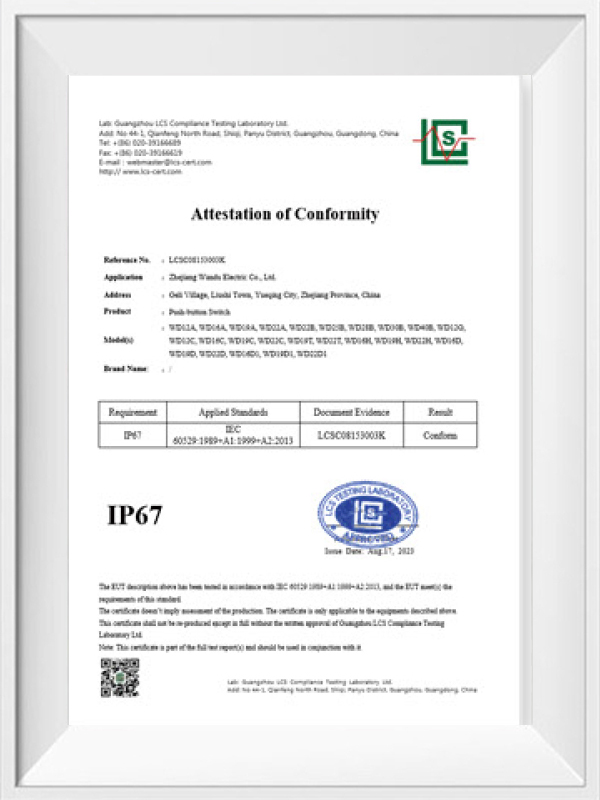

Waterproof Emergency Stop Pushbuttons are designed for environments where moisture exposure is unavoidable. This may include outdoor machinery, washdown areas, marine equipment, or food processing lines where cleaning procedures involve water or detergents.

The waterproof function is achieved through sealing elements such as gaskets, membranes, or O-rings that prevent water from entering the switch body. Protection is typically defined by an ingress protection (IP) rating, which specifies resistance to splashes, jets, or immersion. Users should select ratings based on real exposure conditions rather than assuming all “waterproof” devices perform the same.

Beyond sealing, waterproof emergency stop pushbuttons must still meet safety expectations. The actuation force, contact configuration, and visibility should remain consistent even after repeated exposure to moisture. Installation plays a key role here: uneven panel surfaces or incorrect mounting torque can compromise sealing performance. Regular inspection helps ensure that protective elements remain intact over time.

What Makes a Mushroom-Shaped Emergency Stop Button Effective?

The Mushroom-Shaped Emergency Stop Button is defined by its large, rounded actuator head. This shape is not aesthetic; it is designed for fast, unmistakable activation during stressful situations.

The enlarged surface allows the button to be pressed with a hand, elbow, or other body part, reducing reaction time when fine motor control may be limited. This design supports intuitive use, especially in environments where operators may wear gloves or need to act quickly.

Many mushroom-shaped emergency stop buttons incorporate a latching mechanism. Once pressed, the button remains in the activated position until it is deliberately reset, often by twisting or pulling. This ensures the stop condition is maintained until the situation is reviewed. For system designers, pairing this button with clear labeling and contrasting colors helps ensure instant recognition across different users and shifts.

How Do These Components Work Together?

While each device has a distinct role, their interaction defines overall safety behavior. A mushroom-shaped emergency stop button provides rapid stopping capability. Waterproof emergency stop pushbuttons ensure that this function remains available even in wet or harsh environments. The reset button switch then manages recovery, requiring deliberate confirmation before operation resumes.

This separation of functions reduces ambiguity. Operators know which control stops the machine, and which one prepares it to run again. For maintenance teams, it also simplifies troubleshooting by clearly defining each stage of the safety sequence.

Practical Reflections for Safer System Design

Viewed as a group, these components illustrate how safety is enforced through both hardware design and user behavior. Reset Button Switch devices manage acknowledgment and recovery, Waterproof Emergency Stop Pushbuttons protect critical functions in moisture-prone environments, and Mushroom-Shaped Emergency Stop Button designs focus on rapid, intuitive activation. When each is selected and installed according to its role, the result is a control system that responds predictably under stress and supports safe operation during normal use. This clarity helps protect personnel and equipment alike, not through complexity, but through thoughtful separation of responsibilities within the control interface.

русский

русский Español

Español